Michael Bove

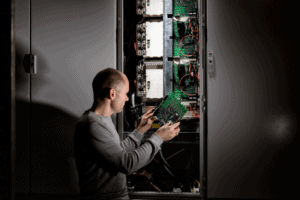

KK Wind SolutionsEfficient test system increased production capability

Problem

KK Wind Solutions is a leading player in electro-mechanical systems for wind turbines. Demand for their products is high, and their old test system slowed down production speed. The company needed an automated manufacturing test of their wind turbine control systems in order to increase test coverage and decrease test time, and so that production volume could be increased rapidly. Also, it was important that the system was easy to duplicate at the company’s production sites around the world.

Solution

CIM designed a test system based on the NI TestStand test management environment with the modular NI PXI and SCXI hardware. This platform provided instrumentation and signal conditioning slots as well as an industry-standard solution for future compatibility. We also added custom step types to the platform – a specific test that is easy to add and configure for a nonprogrammer in NI TestStand.

Result

As a result, KK Wind Solutions can now automatically test all functions in their products, which provides a clear competitive advantage in the market. Cabinet testing time has been cut down from five days to one day, making it possible to increase production capacity. The clear architecture of the system makes it easy to implement at all production sites – the system is simply connected to the network, and then it automatically configures itself using the configuration information in the database.

“We cut the test time of our cabinets from five days to one day, making it feasible to increase production capacity. Now we can automatically test all of the functions of our products, which gives us a clear competitive advantage in the market.”

CASES

Related cases

Case

Dantherm: Track & Trace system with full ERP integration

Case

Deif: Integrated production IT system ensures competitive advantage

Case

Danfoss Heating: Data collection from thermostats provide energy use insights

Case

Grundfos: No-code vision platform reduces installation time

Case

Stevanato Group: Serialization retrofit solution brings compliance up to date

Contact our specialist in Test

Dennis Morini, Business Development Manager