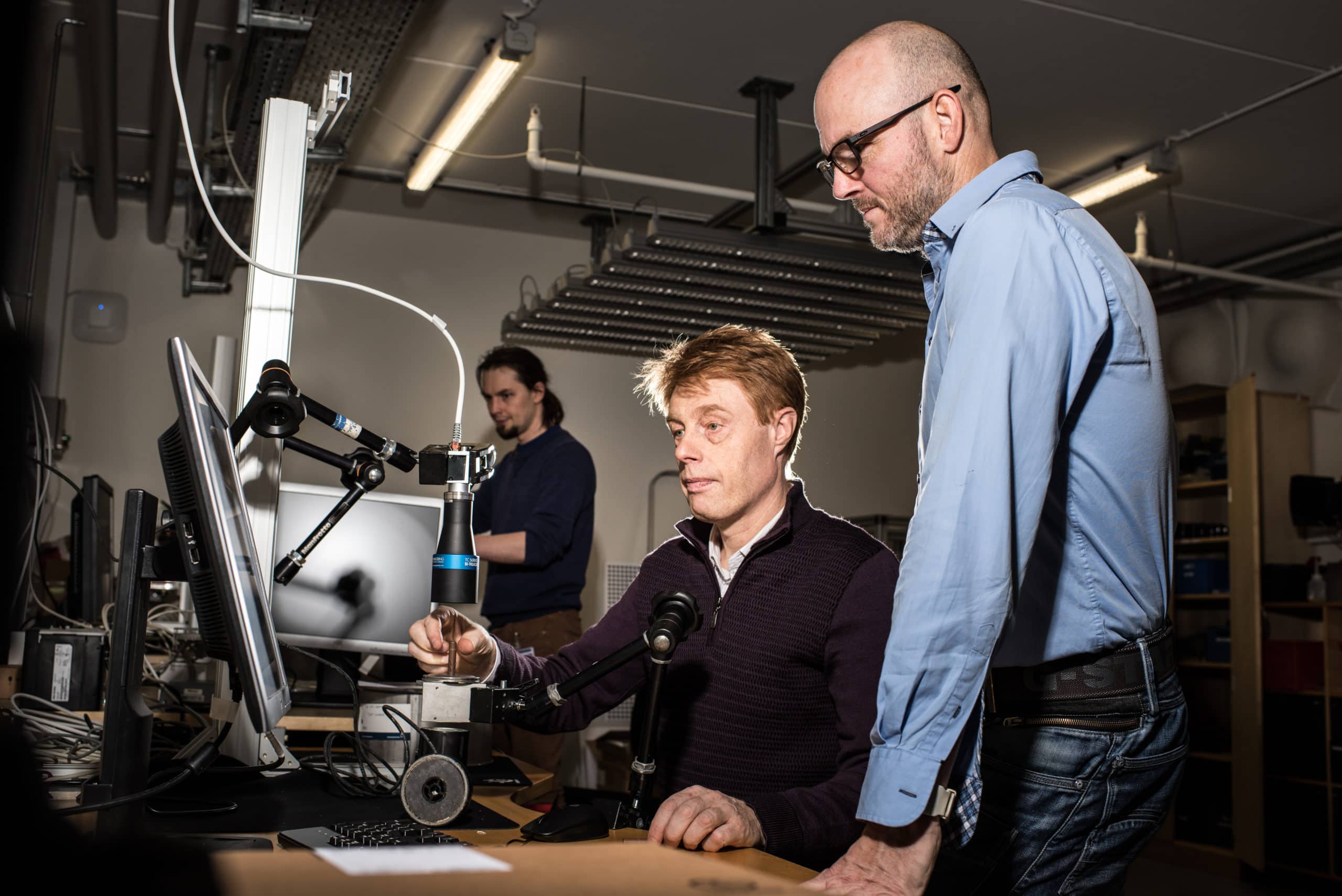

Jan Bigum

Lead EngineerGrundfos Production IT

Grundfos: No-code vision platform reduces installation time

Now, the pump manufacturer Grundfos may easily and quickly configure new vision solutions in the manufacturing process without programming.

Vision platform developed in collaboration with CIM.AS facilitates this.

Problem

Since 2003, vision systems have played an important role in Grundfos’ quality assessment of their pumps. However, for the first ten years, Grundfos had no solid vision platform to rely on when manufacturing staff called and asked for the development and installation of a new vision solution. That meant that building the vision solutions was time-consuming and expensive. Every time a request came in, 50% of the solution had to be developed from scratch, because Grundfos couldn’t reuse the code from previous projects. Grundfos decided that a standardized solution was required.

Solution

CIM was brought in to develop a standardized vision framework that would ease the process of developing new vision solutions and make it easier to roll out existing ones to the 56 countries with Grundfos production sites.

CIM created a platform that provided Grundfos with all the benefits they were looking for:

Result

The new vision platform significantly reduces the installation time for new vision solutions anywhere in the manufacturing process. And since coding skills in LabVIEW are not necessary, a much wider range of people are able to implement a new vision solution in the manufacturing process.

”We often receive requests for the implementation of new functions and now we are able to develop it ourselves and patch it into the existing framework. This lends us a very high degree of flexibility, which we would not have with a piece of finished software" says Jan Bigum, Lead Engineer of the Grundfos Production IT Department

This also benefits Grundfos colleagues in other countries. Jan Bigum says: ”Now, we have a thoroughly tested vision platform which just needs configuring, and that means that our colleagues are able to focus on technical vision issues, whether the solution is to be implemented in France or in Serbia. Manufacturing staff becomes self-supporting to a high degree and things just run more smoothly”

Anders Meister, Sales Director in CIM, says: “We can quickly implement similar solutions elsewhere in the industry sector – we can offer a solution to classical machine vision tasks at a competitive price and at low risk”.

Jan Bigum

Lead Engineer

CASES

Case

Case

Case

Case

Case

Mick Pelby, Business Development Manager