Track & Trace system with full ERP integration provides full control

Problem

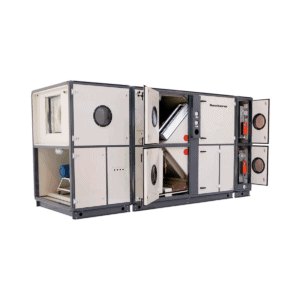

Dantherm is a leading worldwide provider of air handling systems for heating, heat recovery, cooling, air-conditioning, drying, and ventilation. The company was experiencing quality problems in their production which resulted in expensive rework processes. To resolve this, they needed a system for data capture and production control which integrated fully with their ERP system and the test systems on the production lines.

Solution

CIM developed a Track & Trace system for Dantherm based on barcode marking and scanning. A barcode label is printed for each device part in a given order. This barcode follows the device throughout the entire process – from start-up until the device is placed in the warehouse and eventually shipped to the customer. The system includes:

- Fully integrated IoT Track & Trace system

- Barcode on all parts that go into production of the device

- Tracking of which materials are assembled into a given device

- Quality control measuring – through electrical testing of device

Full integration to ERP and ware housing system

Result

As a result, Dantherm now has a fully automated value chain from material entry over production quality control to warehousing. Everything is connected with push control and pull result from/to the company’s ERP system. The result is complete control over the production process, increased product quality, and drastically reduced rework processes.

CASES

Related cases

Case

Dantherm: Track & Trace system with full ERP integration

Case

Deif: Integrated production IT system ensures competitive advantage

Case

Danfoss Heating: Data collection from thermostats provide energy use insights

Case

Grundfos: No-code vision platform reduces installation time

Case

Stevanato Group: Serialization retrofit solution brings compliance up to date

Contact our specialist in Track & Trace

Anders Meister, Chief Sales Officer