Quick and accurate line clearance

Our system for automated line clearance supports operators in their work and help shorten batch changeover time while ensuring a high level of accuracy.

- Reduce inspection time by up to 75%.

- Digital batch documentation always ready for audit.

- Based on fully validated GAMP Cat. 4 software

- ROI in days. Yes, days.

Line clearance eats production time. But it doesn't have to.

While operators manually check the line for rogue components and document the process, the clock is ticking. Often well past the 60-minute mark.

And despite detailed SOP's and checklists the risk of human errors is ever present.

With a future of smaller batches and multiple daily BCOs, these challenges are only getting bigger. So why not take advantage of new technologies and do something about it?

Ready for the next batch in 3 simple steps

Automated line clearance for world-class OEE

An automated line clearance system based on machine vision completes inspections quickly, consistently and repeatably.

The outcome?

Improved line availability and higher throughput – perhaps even to the extend where new line investments can be postponed.

Significant OEE improvements mean that the average ROI is counted in days.

Know with certainty. And document it.

Reduce risk by not relying on the human eye and meet auditors’ demands at any time with comprehensive documentation that details exactly what has happened, which actions were taken and by whom.

- Full clearance report on completion

- Timestamped reports and images are easy to find

- Built-in audit trail and compliance management

- Tracks both users and line clearance activities

- Report log file for all previous clearance activities

Automating line clearance benefits operators too

- No more spending massive amounts of time on paperwork.

- Less bending out of shape to check hard-to-reach areas for rogue components.

- Fewer worries about whether you missed something.

CIM LineClear guides operators through the line clearance process by means of a color-coded overview of both automatically cleared sections, manually cleared sections and failed inspections.

A solution built on proven technology

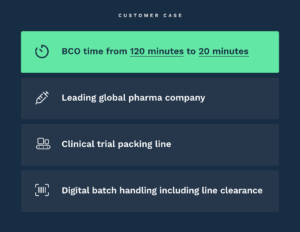

BCO time reduced by 83 %

Production lines for clinical trials are the epitome of small batches. The meticulous documentation of every single batch and item means lots of time spent between batches on document handling and line clearance.

Our customer, a leading global pharma company, managed to reduce batch changeover time from 120 minutes to 20 minutes on their packaging line for clinical trials.

The solution comprised a fully digitized batch handling workflow, including line clearance.