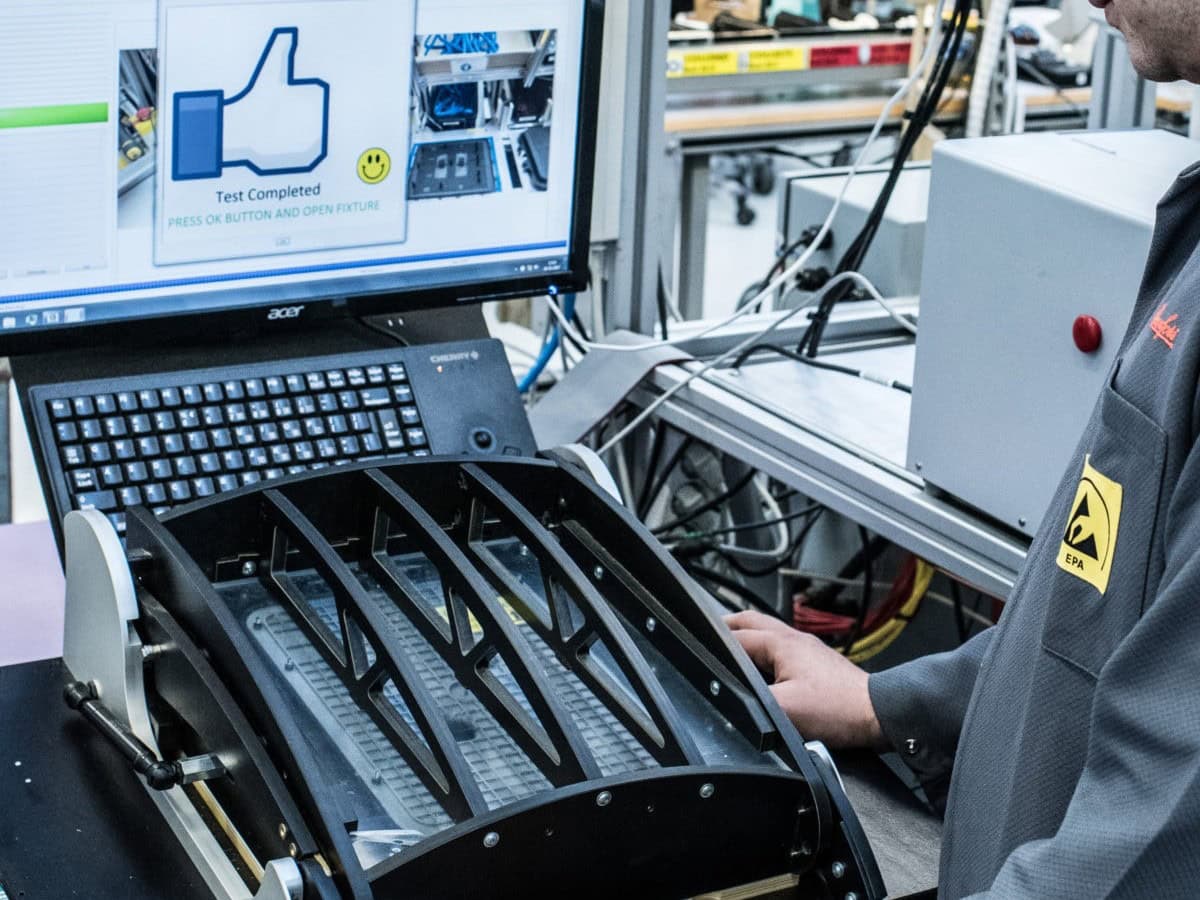

Automated test solutions

Whether we’re talking field, lab or production testing, a reliable automated test solution is a cornerstone in ensuring the very best product quality.

Automated test systems identify defects early, reducing costs and ensuring that every single product meets the desired standard.

Automated test systems keep you in control

Ballooning production costs and disappointed customers are on nobody’s wish list.

So, the more complex electronic products get, the more important it is to stay on top of product quality in every step of the development process. And for global manufacturers, it's crucial that their test systems can grow and adapt with the business.

Solutions for any type of test or industry

We create tailored test and measurement software solutions that help manufacturers control product quality as they ramp up production.

Our solutions cover anything from simple to complex devices, PCBA, final build, off-line and in-line testing.

We engineer our automated test solutions to scale seamlessly, meet future demands and be easy to work with, so that you can focus on what’s important: Testing your products.

Our customers span various industries such as medical devices, defense, renewable energy, consumer electronics and industrial manufacturing.

What our customers say about our automated test solutions

Michael Bove

KK Wind Solutions

Christian Wolf

Global Test Manager

GN Audio

Manager Instrument Plant

Medical device manufacturer

Per Nygaard Hansen

MSC Engineer

Vestfrost Solutions

Christhian Cardona

Senior Test Engineer

Danfoss

Automated test solutions adapted to your specific needs

Flexible, reusable, and reliable components are at the core of any automated test system we build.

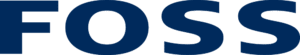

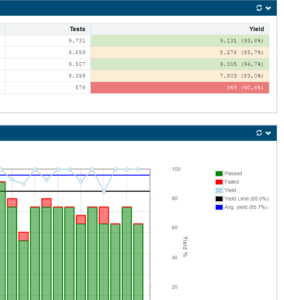

The systems combine industry standard software (LabVIEW and TestStand) with our own software products FlexStand, SeqZap and FACTS. That gives you the benefit of a solution tailored to your needs, but with the proven reliability and scalability of battle-tested, standardized products.

We develop and commission automated test solutions using hardware platforms from technology partners like National Instruments, 6TL and Keysight.

Here are some of the things we can help you with:

Automated test

- Firmware validation test

- Production verification – DUT programming, PCBA and functional testing

- Inline vision inspection

Datalogging, monitoring and control

- Off-shore structural datalogging/monitoring

- Life-time test in lab with test rack control

- Prototype testing

- Material validation

Browse our products for automated tests

LabVIEW and TestStand experts

Our certified LabVIEW and TestStand engineers are ready to help you with any kind of test project.

As Denmark’s leading LabVIEW and TestStand experts, we have created test solutions since 1998, and we’d be happy to use our skills to deliver an automated test solution that fits your exact needs.

What to expect from a CIM test project

A test solution from CIM doesn’t just focus on the test specification. We always begin by understanding your operational requirements.

We want to know your expectations to uptime, ease of maintenance, lifetime, etc. – all to ensure that you get a solution that supports your processes in the best possible way.

Transformational stories from our customers

Case

GN Audio: Efficient audio device test with higher coverage

Case

Test system built for global scalability

Case

KK Wind Solutions: Test system increases production capacity

Case

Danfoss: Standardized test solution reduces lifetime costs

Case

Vestfrost: Test system with zero interference despite extreme conditions

Should we develop your automated test solution?