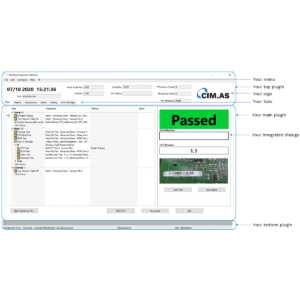

Automated test solutions for any type of device test

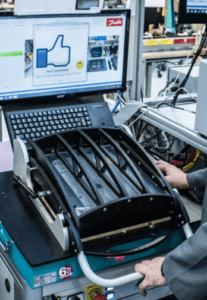

With decades of experience within the field, we offer standardized automated test solutions for anything from simple to complex devices, PCBA, final build, off-line and in-line testing.

Standardized test solutions adapted to your specific needs

Flexible, reusable, and reliable components are at the core of any test system we build.

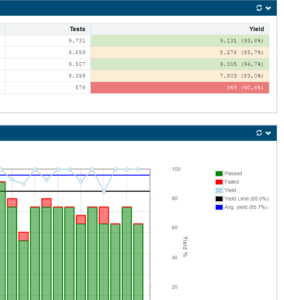

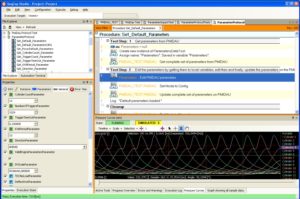

Combining industry standard software (LabVIEW and TestStand) with our own software products FlexStand, SeqZap and FACTS, we develop and commission hardware platforms from companies like National Instruments, 6TL and Keysight.

With these standardized puzzle pieces, we can put together an automated test solution that matches your exact requirements. Browse our products below.

What to expect from a CIM test project

A test solution from CIM doesn’t just focus on the test specification. We always begin by understanding your operational requirements.

We want to know your expectations to uptime, ease of maintenance, lifetime, etc. – all to ensure that you get a solution that supports your processes in the best possible way.

Transformational stories from our customers

Case

GN Audio: Efficient audio device test with higher coverage

Case

Test system built for global scalability

Case

KK Wind Solutions: Test system increases production capacity

Case

Danfoss: Standardized test solution reduces lifetime costs

Case

Vestfrost: Test system with zero interference despite extreme conditions

Should we develop your next test solution?