Correct medication dose with vision technology

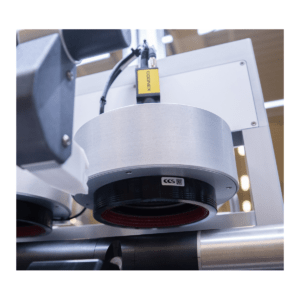

For 100% quality control of injection pens, Stevanato Group relies on CIM SPECTS to verify the important steps of the assembly process.

The challenge

SVM, a Stevanato Group brand, develops unique assembly systems for the assembly and installation of all types of items and materials.

This automated solution assembles hormone injector pens with high focus on quality and performance.

This requires 100% quality control using inspections to verify the important steps of the assembly process.

As the machine supports different pen formats, the inspection system is required to support recipe execution. Also the system is required to be in regulatory compliance.

The solution

We solved the challenge with our vision platform CIM SPECTS, configuring the required standard inspections for

- Mix up Test

- 360 Inspection

- Device Inspection

- Label Inspection

- Label on device Inspection

To ensure regulatory compliance, we used the GxP data handling system CIM TRACKS for user management and audit trail.

The outcome

As a result, Stevanato Group can provide their customers with future proof solutions that are easy to use, flexible in terms of format changeovers and stable in operation, while delivering exceptionally high performance.

Related cases

More transformation stories from our customers

Looking for a standardized, yet adaptable inspection system?