LabVIEW and TestStand: Test software built on the industry gold standard

As Denmark’s leading LabVIEW and TestStand experts, we have created automated test solutions since 1998.

We specialize in developing automated testing and industrial data logging and monitoring software solutions using LabVIEW & TestStand.

Trusted by market leaders

Do you struggle with a lack of LabVIEW and TestStand resources?

When your focus is developing and testing products, it can be hard to stay on top of everything LabVIEW and TestStand at the same time. Not to mention that developing and supporting test systems in-house can take a heavy toll on resources and require specialist skills that are hard to come by.

We are the experts, so you don't have to be

With decades of experience, our consultants develop and support test systems using LabVIEW and TestStand, so that you can focus on what you do best.

LabVIEW and TestStand from NI are the industry gold standard, and we’re proud to be one of only 15 certified NI Centers of Excellence worldwide.

Our certified LabVIEW and TestStand engineers are ready to help you with any kind of test project.

Certified LabVIEW/TestStand engineers and developers

As Denmark's leading LabVIEW and TestStand consultants, we create tailored test and measurement solutions for field, lab and production testing that help manufacturers control product quality, ramp up production or accommodate new product variants.

Combining LabVIEW and TestStand with our own software products, our expert engineers and developers design solutions that are easy to work with, scale seamlessly and are designed to meet future demands. Our customers span various industries such as medical devices, defense, consumer electronics and industrial manufacturing.

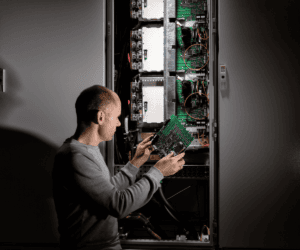

Our TestStand solutions improve the quality and efficiency of PCBA (Printed Circuit Board Assembly) testing. By leveraging TestStand’s capabilities to automate the execution of complex test sequences, our test solutions reduce manual intervention and increase repeatability. TestStand’s powerful data management features allow us to provide detailed reporting and analysis, ensuring that all test data is accurately captured and easily accessible.

References

What our customers say about us

Michael Bove

KK Wind Solutions

Manager Instrument Plant

Medical device manufacturer

Christhian Cardona

Senior Test Engineer

Danfoss

Christian Wolf

Global Test Manager

GN Audio

Per Nygaard Hansen

MSC Engineer

Vestfrost Solutions

Our LabVIEW and TestStand capabilities

Testing time down from five days to one

Challenge

To quickly ramp up production, KK Wind Solutions wanted a test system that would increase test coverage, decrease test time and allow for a smooth global roll-out.

Solution

A test system based on NI TestStand with modular NI PXI and SCXI hardware plus custom step types, easy to configure without extensive TestStand skills. New systems autoconfigure using the configuration information in the database.

Outcome

Automatic test of all product functions. Reduction in cabinet testing time from five days to one has increased production capacity. New systems are easy to add.

With CIM as your test & measurement partner you get:

- Access to highly skilled LabVIEW and TestStand engineers for development, training and support - whenever you need.

- Robust, scalable test solutions built on industry standard software from NI and CIM.

Need help with a test project?