Industrial IoT solutions

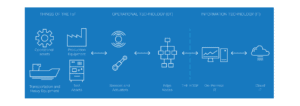

Our Industrial IoT solutions cover all parts of the data flow and can integrate with any measuring devices, components or systems.

All levels of IIoT covered: data collection, edge computing, data connectivity, storage, presentation, and decision making.

Industrial IoT for intelligent manufacturing

Manufacturers use CATCH.AI to maximize productivity with decision support for all teams, based on real-time data from their machines.

Capture, store and access all production data in one application

- Go beyond surface metrics like OEE that offer no real guidance on how to improve performance.

- Know what is working and what is not when running in new production lines.

- Ditch homemade databases and excel sheets and spend less time preparing and cleaning data.

- Avoid the siloed insights that come from a fragmented data ecosystem.

- Stop relying only on the gut feelings of operators and technicians for solving production issues.

Stay ahead of downtime with decision support

CATCH.AI helps manufacturers improve OEE by providing key roles with decision support based on live data from the production line.

Watch the video to see how technicians can use data to predict and address issues before they impact production.

Data-driven insights in a box – no IoT experience required

The first step towards data-driven insights is to collect data.

With preconfigured sensors, cameras and ready-to-run software, the CATCH.AI starter kit makes detailed process data available in a matter of minutes.

It's easy data collection, straight out of the box.

Industrial IoT cases

Transformational stories from out customers

Need help connecting your devices?